Celebi YILDIRIM

Design Engineer

Hi, I'm Çelebi Yildirim, a design engineer based in Hamilton, New Zealand. I specialize in mechanical design, system design, project management, and end-to-end engineering solutions.With over 15 years of engineering experience, I have worked on engineering projects in New Zealand, first at Hansa Products Ltd and later as a co-owner of Ark Security Ltd. Before moving to New Zealand, I gained extensive experience in Turkiye on major military and industrial projects and collaborated with clients across Europe, Japan, and the United States.Explore my resume, expertise, projects, and contact details to learn more.

About Me

I am a mechanical design engineer who combines technical expertise with practical problem-solving. My work focuses on delivering reliable, efficient, and innovative solutions — from early concept design to prototyping, certification, and on-site implementation.I have extensive experience in mechanical design, project management, and collaborating with teams and clients. I excel in projects that require strategic planning, attention to detail, and a holistic view of the design and engineering process.Since moving to New Zealand in 2018, I have been actively contributing to engineering projects while continuing to grow my expertise.Outside of work, I deeply value my family. My wife and young son are my greatest inspiration, and I enjoy spending quality time with them while balancing my professional life. They keep me motivated and remind me of what truly matters.

Experience

Ark Security Ltd – Hamilton, NZ | Feb 2023 – Present

Co-owner and design engineer applying mechanical engineering expertise to system design, installations, and project management. Strengthened hands-on skills in diagnostics, system integration, and client-focused delivery while managing business operations.

Experience

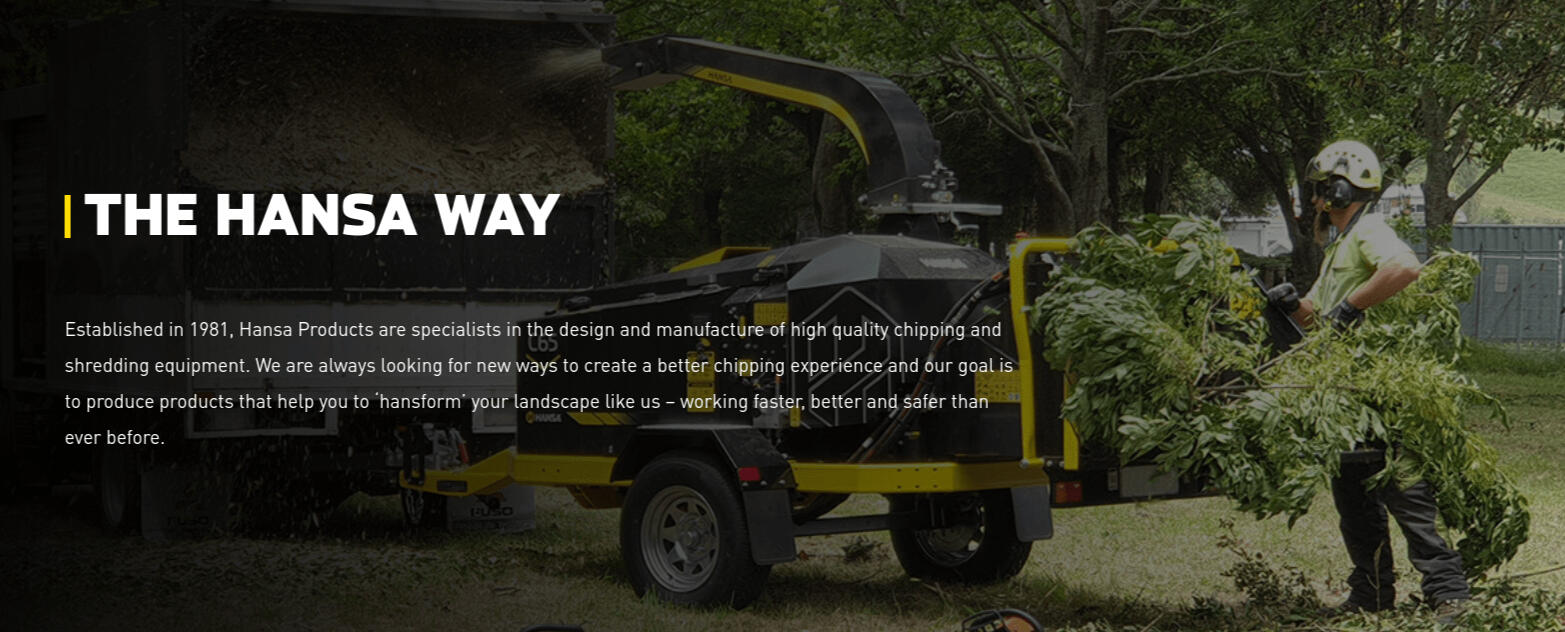

Hansa Products Ltd – Hamilton, NZ | Jul 2018 – Feb 2023

Mechanical design engineer for a leading New Zealand chipper manufacturer. Responsible for product development, design enhancements, prototyping, and improving production efficiency through innovative jigs, fixtures, and workflow optimization.

Experience

Earlier Roles – Turkiye | 2010 – 2018

Extensive mechanical design and project management experience across prestigious national and international projects, including:

ALTAY Main Battle Tank Project – mechanical design for key subsystems of Turkey’s first national main battle tank

Robotics & Autonomous Vehicles – design and prototyping for commercial and military unmanned vehicles

International Glazing Projects – full project management for marine, railway, and architectural glazing, coordinating engineering, production, and delivery for clients in multiple countries

Projects

Hansa Wood Chipper CE Certification – Hansa, New Zealand

Hansa manufactures 2–64 hp wood chippers in New Zealand and was expanding into the Australian and European Union markets during my time with the company. I led the CE certification process for all models destined for the EU. This involved reviewing all relevant AU/EU machinery standards and legislation, designing the required custom test jigs and apparatus, carrying out the full test program, and documenting every stage to meet compliance requirements. After successfully completing the testing and reporting, I secured CE certification for the product range, enabling Hansa to grow in the EU market.

Projects

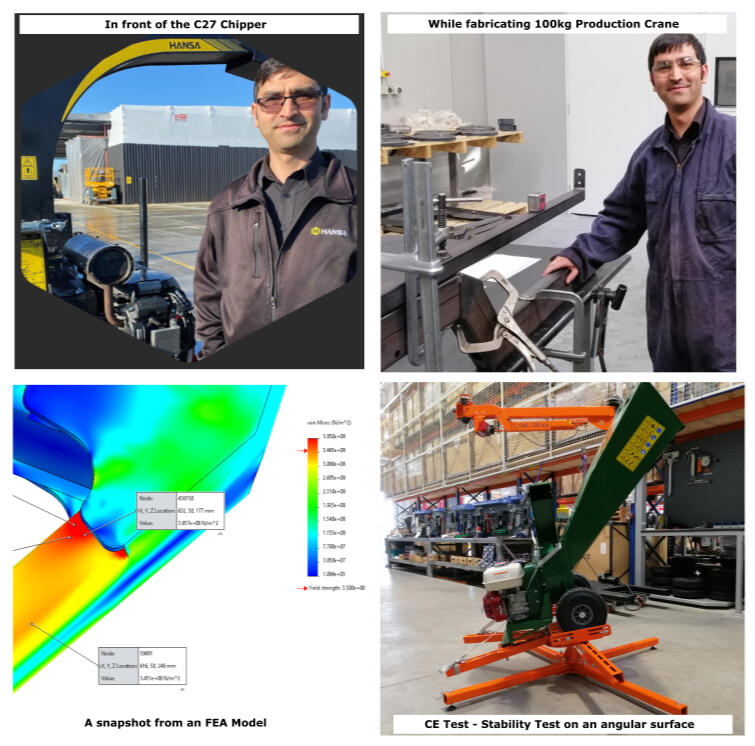

Istanbul Ulasım RTE T4 – 1st Domestic Tram - BCE, Turkiye

Istanbul Ulasım A.S., a government-owned transportation company, designed Türkiye’s first domestically produced tram for the RTE T4 line. I worked with their engineering team to deliver the full glazing package for the vehicle. My primary responsibility was designing the control cab’s glass panels, including several heated and complex-geometry windshield units that were challenging to manufacture. Despite the technical difficulties, I successfully completed the design and supported production to ensure all panels met the required performance, safety, and quality standards. The project was delivered with excellent results, and the tram entered service with fully compliant and reliable components.

Projects

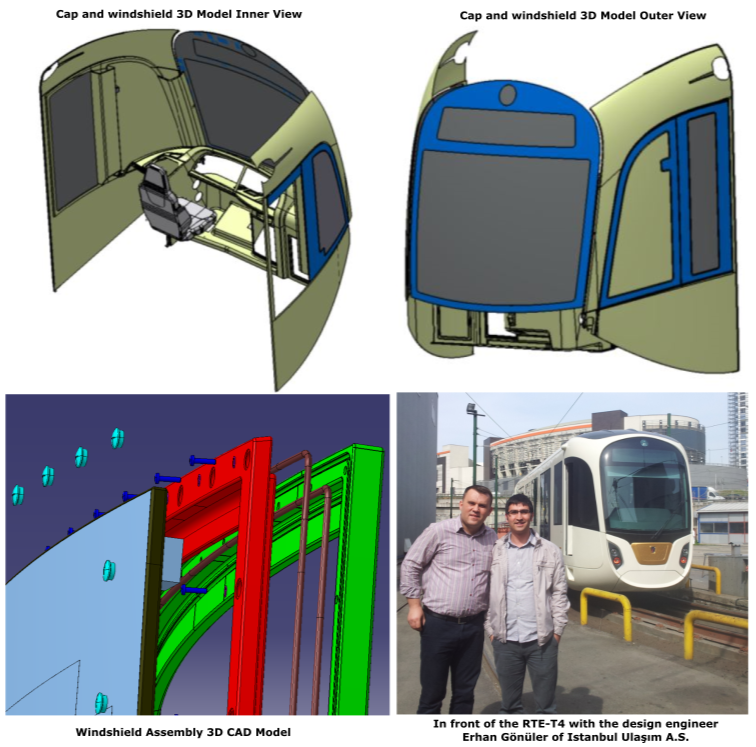

Feadship Como Superyacht (688) Glazing in NL - BCE, Turkiye

Feadship Como is a 46-metre superyacht designed by Dubois and built by De Vries Aalsmeer in the Netherlands, where BCE was responsible for delivering the complete glazing package. The project featured double-curved, chemically tempered glass (an extremely complex material to certify, measure, and manufacture) making it one of the more challenging glazing scopes in the industry. As the Project Leader Engineer during the design phase, I coordinated resources, schedules, and technical workflows to ensure precise execution and high-quality results. Despite tight timelines and the technical difficulties of the glass geometry, we successfully delivered the glazing system on time and to full client specifications. To meet Feadship’s expectations for reduced glass thickness, I also designed two hydrostatic test machines in accordance with ISO 11336-1, enabling us to validate performance using advanced methods. The Feadship team was highly satisfied with the final outcome.

Projects

ALTAY Main Battle Tank Project – Otokar, Turkiye

I contributed as a mechanical systems designer for the ALTAY Main Battle Tank, Turkiye’s first national main battle tank. The project involved the design and production of four complex vehicles to meet the tactical and technical requirements of the Turkish Armed Forces.

During the project, I was responsible for designing three key mechanical subsystems, which were successfully produced and integrated. This challenging and high-profile project required precision, problem-solving, and collaboration under tight deadlines, and I received commendations from both the military and my managers for my contributions.

Projects

Gelibolu – Türkiye’s First Domestic Work-Class ROV

Gelibolu is Türkiye’s first domestically developed work-class Remotely Operated Vehicle (ROV).

During my time at GATE Elektronik, I was responsible for the entire mechanical design, including component development, assembly layouts, production drawings, and design-to-manufacture support. Gelibolu was showcased at the IDEF 2011 International Defence Industry Fair in Istanbul, where it attracted significant attention.

One of the highlights of the event was a visit by the 11th President of the Republic of Türkiye, Abdullah Gül, who viewed the Gelibolu ROV during his tour.

My Engineering Contributions:

- I led the mechanical development from concept to manufacturing, including: Selection and sourcing of components (prioritising domestic suppliers)

- Design of several subsystems such as: Underwater robotic manipulator arms, thrusters, torches, cameras and full mechanical design of the complete work-class ROV.

- Technical documentation, production drawings, and coordination with manufacturing teams

Resume

My full resume is available upon request. Please click the “Contact Me” button below, and I’ll be happy to share it with you.

Gallery

A selection of photos from projects and work over the years.

Contact Me

Whether you’d like to talk about a project, explore a potential role, or simply connect, I’d be happy to hear from you.

Thank you

Your message has been received, and I’ll reply soon.